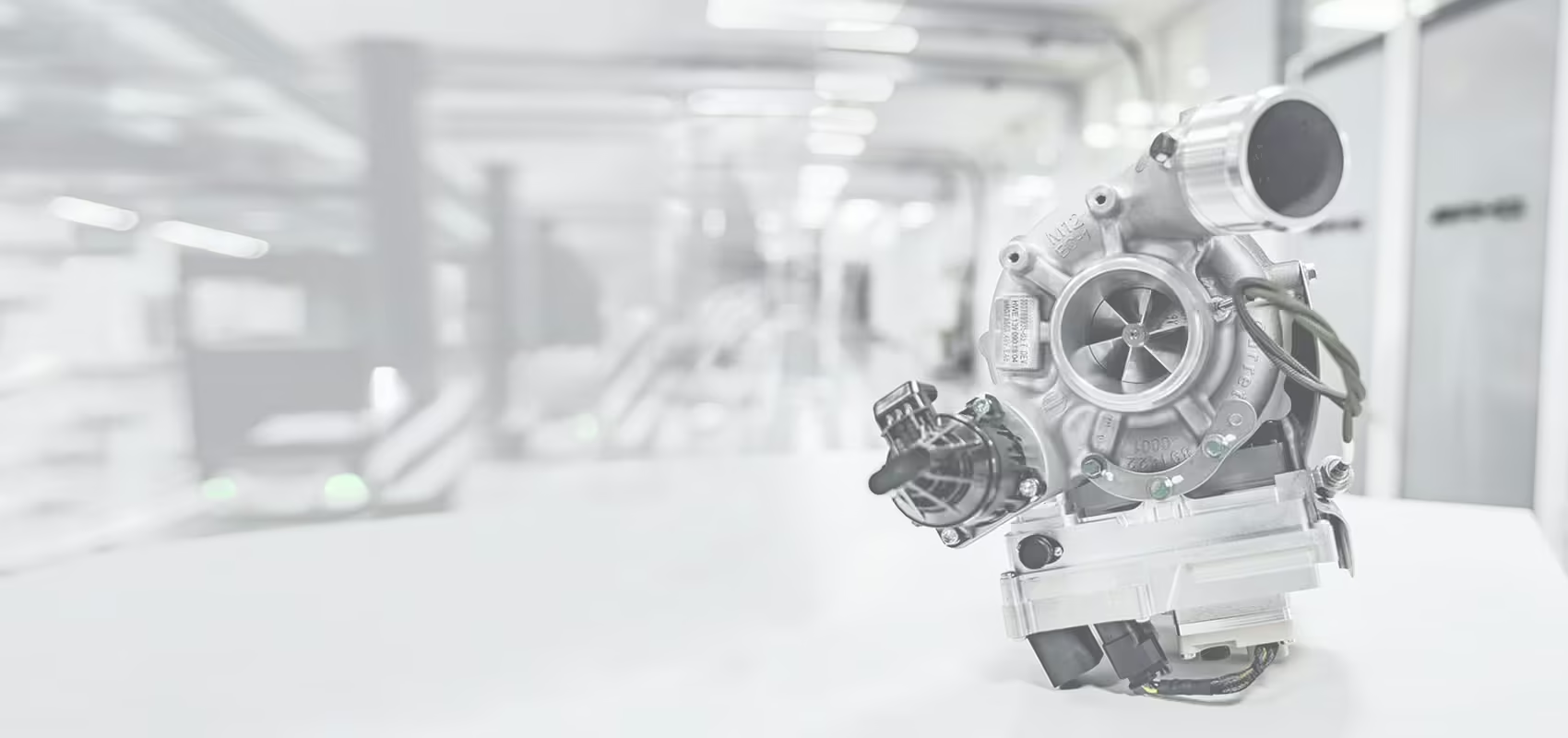

Core Structure and Materials of Turbochargers:

A turbocharger comprises three primary components: the turbine (including the volute, nozzle ring, and turbine wheel), the compressor (with an intake duct, centrifugal impeller, diffuser, and compressor housing), and the center housing, all interconnected via a precision floating bearing system.

Key material innovations include:

Turbine Wheel: Constructed from nickel-based superalloys (e.g., Inconel 718) or ceramic matrix composites (Si₃N₄), capable of withstanding temperatures up to 950°C.

Floating Bearing: Utilizes dual-layer oil film lubrication (inner clearance: 0.05mm, outer: 0.1mm) to sustain rotational speeds exceeding 150,000 RPM.

Sealing System: Integrates gas and oil seals to prevent lubricant ingress into combustion chambers, mitigating oil consumption issues.

Thermodynamic Principles and Efficiency Optimization:

Exhaust Energy Recovery: High-temperature exhaust gases (600–900°C) drive the radial turbine wheel at speeds up to 180,000 RPM, converting thermal energy into rotational force.

Air Compression: The coaxial compressor impeller pressurizes ambient air to 1.3–2.5 bar. Post-intercooler cooling (60–80°C temperature reduction) increases air density by 30%, enabling a 1.5L turbocharged engine to match the power output of a 2.0L naturally aspirated engine.

Combustion Enhancement: Enriched oxygen levels reduce the air-fuel ratio from 14.7:1 to 12.5:1, boosting specific power output by 30–40%.

Technical Advancements and Industry Applications

Variable Geometry Turbines (VGT): Adjustable guide vanes optimize exhaust flow across RPM ranges, reducing turbo lag to 1.2 seconds (e.g., Porsche 911).

Electric Turbocharging: Mercedes-Benz M256 engines employ 48V electric assist turbines, improving low-end torque response by 40%.

Material Breakthroughs: BorgWarner’s TiAl turbine wheels reduce weight by 40%, paired with silicon nitride ceramic bearings for 300,000-km durability.

Operational Guidelines and Maintenance

Cold Start Protocol: Idle for 90 seconds post-start to ensure oil temperature exceeds 60°C (critical for 0W-40 synthetic oil viscosity).

Post-Drive Cooling: Maintain 2-minute idling after high-load driving to prevent bearing temperatures exceeding 300°C, avoiding oil coking.

Scheduled Maintenance: Clean compressor wheels every 30,000 km—0.1mm of carbon buildup can reduce efficiency by 15%.